Incorporating the use of PUF sandwich panels in Moga is an imperative means to ensure the best thermal efficiency and temperature retention which prevents energy losses. These panels are also utilized to control the noise levels and the top acoustic panels supplier in Moga EPACK offers innovative sandwich panels with exceptional strength and sustainability benefits. These panels help maintain leakproof enclosures and allow for extended indoor temperature consistency. EPACK follows the top levels of quality control as well as testing to produce these panels and guarantees on-time delivery of the same.

Sandwich Panels Manufacturer in Moga

Composite Sandwich Panel Features

The use of PUF sandwich roofing sheets in Moga has been popularised owing to the amazing benefits these panels deliver. Some of the top-rated features from these composite panels include –

- Myriad choices and options for finishing

- Corrosion, termites, fire and impact resistance

- Unparalleled thermal and noise insulation

- Leakproof design and temperature retention

- Low thermal conductivity and top-level longevity

Composite Sandwich Panels Applications

The use of PUF insulation panels in Moga brings vital advantages in construction and helps target peak sustainability and energy savings as well. Some of the top applications of these composite panels include –

- Healthcare units and office building envelops

- Cinema halls and concert theatre acoustic panels

- Panels for office enclosures and residential apartments

- Pharmaceutical sector and prefab shelters

- Noise insulation panels for factories and industries

Our Quality Offerings

Prefabricated Structures

EPACK Prefab’s prefabricated structures provide efficient and versatile solutions for various applications. Our dry construction process ensures rapid assembly and high-quality results.

Sandwich Panels

EPACK Prefab manufactures sandwich panels in India, offering a range of insulating panels for various industries, including agriculture, office buildings, healthcare facilities, and warehouses.

EPS Panels

EPACK Prefab’s EPS panels offer lightweight, energy-efficient solutions for a variety of applications. Known for their excellent thermal insulation properties, EPS panels are widely used in building construction, warehouses, and cold storage. They are cost-effective, easy to install, and highly durable, ensuring long-term performance. With customizable sizes and configurations, EPS panels provide flexibility for diverse construction needs.

Glass Wool Panels

EPACK Prefab’s Glasswool Panels are highly effective in insulation, offering excellent thermal and acoustic properties. These panels are lightweight, easy to install, and provide superior fire resistance, making them ideal for both residential and commercial buildings. They help in maintaining energy efficiency while ensuring comfort through temperature control and noise reduction.

PUF Panels

EPACK Prefab offers high-performance PUF panels ideal for a variety of applications. These panels provide superior thermal insulation, energy efficiency, and durability. They are lightweight yet strong, making them suitable for use in buildings, warehouses, and cold storage. PUF panels are designed for quick assembly, offering cost-effective solutions for construction and improving energy savings in industrial and commercial setups.

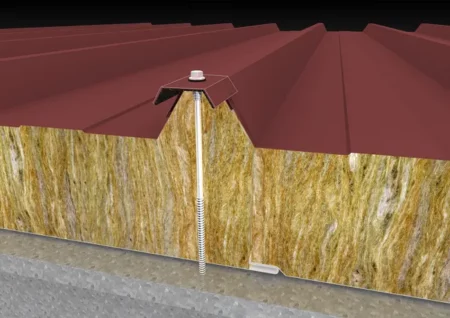

Rockwool Panel

EPACK Prefab’s Rockwool Panels provide superior thermal and acoustic insulation, ideal for both residential and industrial applications. With excellent fire resistance, these panels help improve energy efficiency while offering noise reduction benefits. Rockwool panels are perfect for environments requiring enhanced soundproofing, temperature control, and fire safety, making them a durable and reliable choice for modern construction projects.

Why Choose EPACK Prefab

EPACK as the leading sandwich panels company in Moga stands true to its ethos of ultimate quality assurance and best serving of client satisfaction through development of products that bring exceptional advantages in the construction sector. EPACK is driven by an approach to derive future-ready construction technology solutions with vast scopes of utilization.