Pre-engineered buildings commonly employ steel purlins as secondary structures to support the roof framing below the eaves. As a result of the horizontal diaphragm created by purlins, the weight of the roof and deck can be better supported. Rafters or walls support purlins, which run parallel to the building’s eave. Cold formed steel is the basic material for purlin fabrication. It has a maximum span of 30 feet or more. The proportions of the building’s core frame, as well as its intended use and the engineering design, all influence the length and width. Purlins can be stiffened to prevent structural weakness if necessary. As a result, the roof’s purlins play a vital role.

Steel purlins are commonly seen in pre-engineered buildings of all shapes and sizes. They’re made of lightweight, long-lasting materials that are consistent in their measurements and were constructed with great care. During the summer, purlins extend, whereas during the winter, they contract.

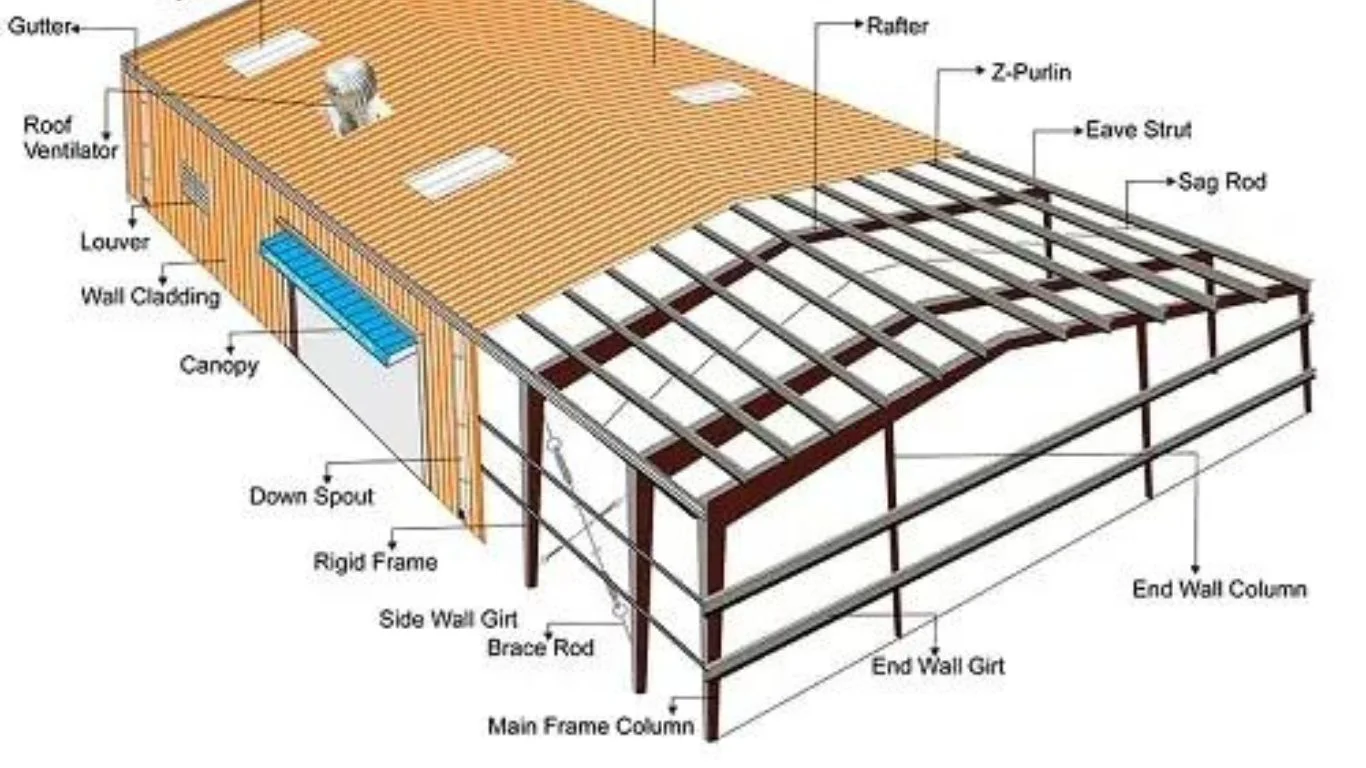

Here are the two most common purlin types:

1. Purlins shaped like C

C-shaped purlins, as their name implies, are what they are named for. Typically, they’re utilised to hold up walls and flooring. If flange stiffeners are present, they are referred to as channel section purlins, and if they are absent, they are referred to as U-sections. C-sections are those that are symmetrical in shape. Lapping these parts is not possible, but their sturdy shape makes them ideal for shipping and storage. Purlins with a high level of stability are commonly employed in clear span design.

2.Purlins shaped like Z

It is also possible to build with Z-shaped purlins, which are more durable. Joints and overlaps are the most prevalent applications for Z-purlins. The major structural system is supported by these purlins, which are located between the roofing sheet and the wall. It is possible to lap Z-purlins by fitting one to another and turning it by 180 degrees.

Purlins and girts have two types of lateral instability: deflection and rotation. A lateral brace for the flange it is fastened to can be created by using engineering procedures like bridging and fixing the sheet with screws. Bridging can help eliminate free flange lateral deflection and section rotation.

As a result, PEBs would be incomplete without purlins. They play an important role in supporting the building’s core frame structurally.