The construction industry is solely responsible for ~39% of global greenhouse gas emissions.

What are we doing as a business in the construction industry?

Recently, India has seen a rapidly growing population and rising human mobility. Due to this, we have also witnessed fast infrastructure development in our Tier 1, Tier 2, and Tier 3 cities. As a result, there is an unsustainable use of natural resources, and carbon emissions are out of control.

Due to all these reasons, we desperately need measures that will help us make the construction sector an eco-friendly industry.

EPACK Prefab, with its pre-engineered buildings and prefabricated solutions, is trying to change the face of this industry with its sustainable construction solutions. The business tries to reduce waste, reuse some of its resources, use eco-friendly materials, and optimize energy consumption for an overall positive impact.

With our green building practices, we assure our clients that their investment aligns with the best environmental practices without costing them a great deal of their budget.

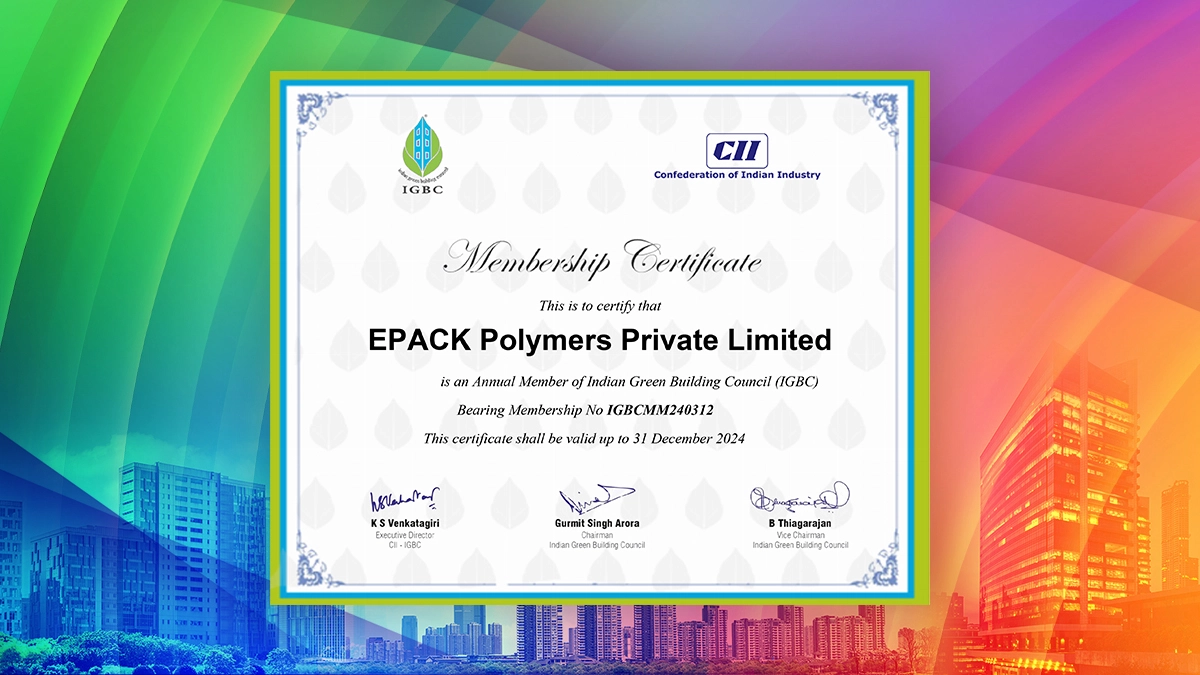

For such green building efforts, we have recently received membership of IGBC, India’s premier membership body for greening projects.

What does membership mean for us as an organization?

Now that EPACK Prehab has become a member of Indian Green Building Council (IGBC), it can further solidify its commitment towards environmental responsibility and sustainability.

As an IGBC Member, EPACK PREFAB has committed to support in reducing carbon footprints, promote ecologically friendly solutions, and make both construction and manufacturing sectors environmentally responsible.

EPACK Prefab’s IGBC membership will help promote its efforts to address the environmental challenges that traditional construction practices pose.

By employing methods where we save energy, recycle materials, and promote conservation, we are setting an example that profits and conserving the environment are not mutually exclusive. It is possible for the construction industry to cater to both goals together.

With IGBC membership in hand, we can now spread these messages forward, we are qualified to be a part of projects and initiatives that give sustainability a priority.

Besides, with the membership, EPACK will also become more open to collaborating with other organisations and stakeholders who share the same passion for making India a more sustainable country.

Why is sustainability necessary in construction?

It’s an open secret that construction companies and their operations are the largest exploitors of natural resources and energy. Besides, the industry is also responsible for causing rampant greenhouse gas emissions.

Organizations that get IGBC (Indian Green Building Council) membership are evaluated rigorously for their environmental performance. They are assessed on the basis of criteria such as efficiency in the use of energy, water conservation, reduction of waste, and use of sustainable materials.

With this membership, we will be able to demonstrate that we are using natural resources and energy options optimally. It will help us show that we meet the highest standards of sustainable practices in the construction and manufacturing arenas.

Why does IGBC membership matter?

As an IGBC member, we are now equipped to foster sustainable products and services that meet the growing demand for eco-friendly solutions. Our membership also enables us to participate in green building projects and contribute to the development of sustainable infrastructure.

This not only benefits our customers but also supports the government’s initiatives to promote sustainable development and reduce environmental degradation.

Our Commitment to Sustainability

Getting IGBC membership is a major feat for EPACK Prefab. We are committed to maintaining and improving our performance in environmental conservation actions.

We are confident that this membership from IGBC will establish ourselves as a reliable partner for green building solutions, and inspire others to follow our footsteps. As a brand, we want to encourage others to adopt more and more sustainable operations in their manufacturing processes.