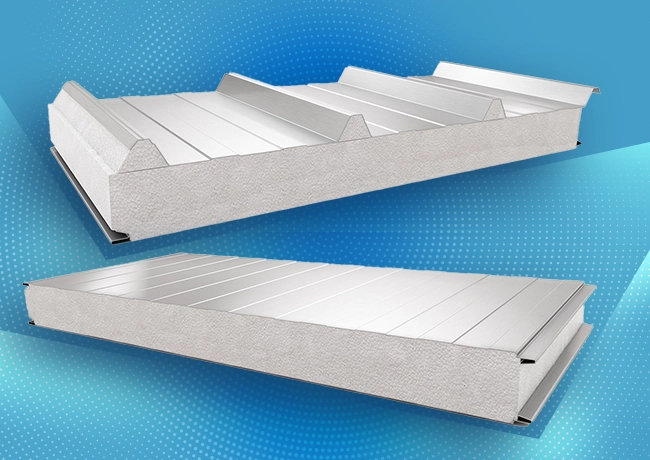

EPACK Prefab offers high-quality EPS (Expanded Polystyrene) core panels, also known locally as thermocol sandwich panels, designed to be a lightweight, affordable solution for cladding, partitions, and thermal moderations. These panels—sandwiched between metal sheets—offer reduced heat transfer, easy installation, and are ideal for non-critical structural or interior applications.

EPS Sandwich Panels by EPACK Prefab — Lightweight, Cost-Effective Cladding & Partition Panels

Key Features & Benefits of Our EPS Panels

- Lightweight & Easy to Handle: Significantly lighter than traditional materials, reducing transportation costs and simplifying, faster installation.

- Cost-Effective: Provides an excellent balance of performance and affordability, offering substantial savings on both material and labor costs.

- Thermal Insulation: The EPS core delivers moderate thermal resistance (R-value), helping to maintain consistent indoor temperatures and reduce energy consumption for heating and cooling.

- Moisture & Pest Resistance: Resistant to water absorption, decay, and pests, ensuring long-term performance and reducing maintenance needs.

- Sound Insulation: Provides good acoustic insulation, helping to reduce noise transmission between rooms or from outside. EPS sandwich panels typically achieve sound insulation ratings between 23-42 dB depending on thickness and construction.

- Aesthetic Flexibility: Available with various external finishes (PPGI, PPGL) and profiles to meet different architectural styles.

- Eco-Friendly Choice: EPS is recyclable and contributes to improved energy efficiency in buildings.

Applications of EPS Sandwich Panels

Our panels are versatile and widely used for:

- Interior Partitions and non-load bearing walls in offices, factories, and commercial spaces.

- False Ceilings and decorative interior cladding.

- Lightweight Roofing and wall cladding for structures in mild climates.

- Cold Storage Interiors for less critical temperature control areas.

- Temporary Structures such as site offices, kiosks, information booths, and accommodation shelters.

- Warehouses & Industrial Sheds where cost-effectiveness is a priority.

Understanding the Best Use-Cases

EPS panels are a fantastic solution, and understanding their fit ensures customer satisfaction:

Ideal For: Cost-sensitive projects, interior applications, temporary structures, and buildings in regions with moderate climatic conditions.

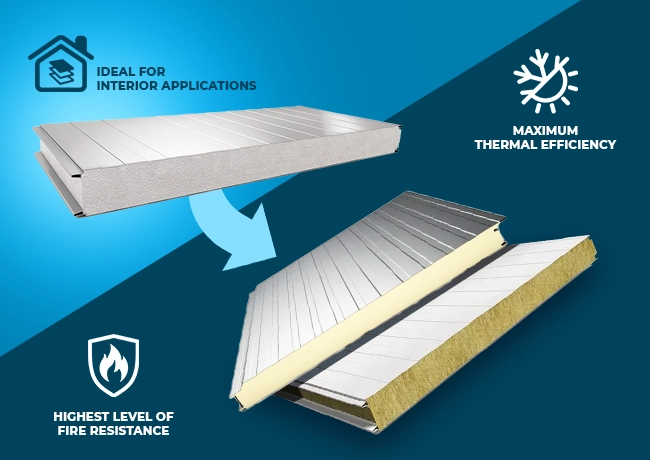

Considerations: For applications requiring the highest level of fire resistance (e.g., high-occupancy buildings, near property lines) or maximum thermal efficiency (e.g., deep-freeze cold storage), we recommend upgrading to our PUF or Rockwool panels.

Why Choose EPACK Prefab for EPS Panels?

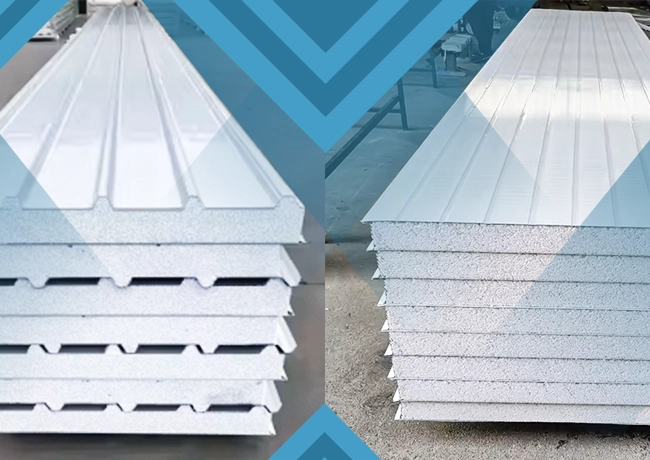

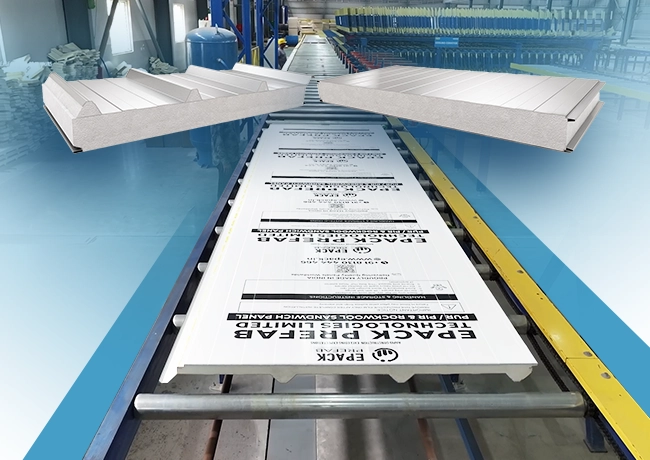

Quality Manufactured: Produced in our state-of-the-art facilities with strict quality control for consistent density and performance.

Custom Solutions: Available in a range of thicknesses and finishes to meet your specific project requirements.

Expert Guidance: Our technical team provides expert support to help you choose the right panel for your application.

Pan-India Supply & Support: We offer reliable delivery and installation support across India, backed by over 25 years of experience.

EPS Sandwich Panel Specification

Frequently Asked Questions

EPS (Expanded Polystyrene) panels are a type of sandwich panel consisting of a rigid thermocol foam core bonded between two durable metal facings. They are a lightweight, cost-effective building material used for walls, roofs, and partitions to provide thermal insulation and a clean finish.

The primary benefits are their lightweight nature (easy to install, lower transport costs), excellent cost-effectiveness, and good thermal insulation. They are also moisture-resistant, offer some soundproofing, and can be customized with different finishes.

They are primarily used for industrial roofing and wall cladding, interior partitions, false ceilings, and for constructing cold storage interiors, temporary site offices, and warehouses where moderate insulation is sufficient.

Yes, they contribute to environmental sustainability. EPS is 100% recyclable. Furthermore, by significantly improving a building’s energy efficiency for heating and cooling, EPS panels help reduce the overall carbon footprint of the structure over its lifetime.

Their lightweight design makes them incredibly easy and fast to install compared to traditional materials. They are typically fixed to a structural frame (like PEB) using specialized screws and weatherproofing seals. Our team can provide detailed installation guidelines or expert on-site support.

They are highly versatile and perform well in most climates, especially moderate ones. For regions with extreme temperature fluctuations or for applications requiring maximum thermal efficiency (like deep-freeze cold storage), we often recommend our higher-performance PUF (Polyurethane) panels.

Standard EPS is a combustible material. However, at EPACK Prefab, we offer fire-retardant (FR) grade EPS that is self-extinguishing and complies with stringent building safety standards. For projects with the highest fire safety requirements, we strongly recommend our non-combustible Rockwool sandwich panels.

EPS panels offer the best balance of cost, weight, and insulation value.

- vs. PUF Panels: PUF has superior insulation (lower K-value) but is more expensive.

- vs. Rockwool Panels: Rockwool is non-combustible and offers better fire safety and acoustic insulation, but is heavier and costs more.

- EPS is the ideal choice where budget and weight are primary concerns, and moderate insulation is adequate.

When installed correctly and maintained properly, EPS panels have a very long lifespan, often exceeding 20-40 years. Their durability is due to their resistance to moisture, pests, and decay, which prevents them from degrading over time.

Yes, the EPS core is 100% recyclable. At the end of its long life, the material can be recycled into new EPS products, supporting circular economy principles in construction.

EPACK Prefab delivers exceptional quality control from our ISO-certified plants. We offer customizable solutions in various thicknesses and finishes, backed by expert technical support and pan-India logistics to ensure you get the right panel, delivered on time, anywhere in the country.

Yes, the dense foam core provides good acoustic insulation.

Yes, they are highly resistant to moisture. The closed-cell structure of EPS prevents water absorption, which safeguards against mold, mildew, and rot, ensuring the panel’s structural integrity and insulation properties remain intact over time.