Prefabricated steel buildings are among the most durable, adaptable, and cost-effective options available. Therefore, it should not be surprising that prefabricated buildings are utilised for a variety of purposes, including a huge number of commercial structures.

To prevent making typical, harmful errors when assembling a PEB steel building, you must be knowledgeable and organised. Such errors can make PEB structures less dependable and less durable, hence increasing expenses.

If you wish to save money, we believe you should avoid the following five mistakes:

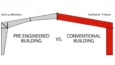

1. Choosing the Incorrect Type of Structure

When constructing and erecting a steel structure, you must consider more than just the correct dimensions. The structure requires in order to fulfil its function. If you require a workshop, you should be aware of its purpose and desired components. The same holds true for a garage, a storage shed, and other structures. Consider the number of windows and doors you desire, whether you require insulation or air flow, where you will place your lighting, and how you will utilise the frame.

You must also demonstrate how your needs evolve over time. You should consider what your current needs are and what they will be in the next five to 10 years. If you construct your building with the years to come in mind, you won’t have to worry about making modifications.

2. Insufficient Work on the Site

A well-designed website ensures that construction continues smoothly. Every building must begin with a stable, level basis. Larger structures may necessitate more complex procedures, such as soil testing to determine the stability of the ground. Additionally, you must give sufficient space surrounding the building for elevator equipment and a delivery van. If you meticulously plan your website, you will avoid delays and costly repairs during construction and for the lifetime of the structure.

3. Incomprehensible dimensions of your building

Too much or too little space is another frequent error that drives up steel building costs. To avoid this costly error, ensure that you know what you want your metal structure to do in the present and in the future. Don’t forget to consider the door’s dimensions. Will your tractor or automobile fit? How many automobiles will you park in the garage? When everything has been successfully saved, is it simple to unlock? Does the size of the windows let sufficient light to enter? Before selecting the final size of the structure, you should consider the following factors. Our experts in steel structures will provide you with accurate information so that you can make informed judgements.

4. Not adhering to the suggestions and precautions

Numerous prefabricated metal constructions are ideal for do-it-yourselfers. Nonetheless, carelessness and lack of preparation can be harmful and costly. All of our steel structure kits include comprehensive, step-by-step instructions for assembling the structure correctly and safely. To keep the builders and the structure safe, be careful to adhere to all of the manual’s safety measures.

5. Communication Uncertainties Regarding Your PEB

When communication is unclear, people develop assumptions that aren’t met, which can result in several issues. It’s possible that something wasn’t made obvious or wasn’t discussed. A lack of clarity in the initial design of the steel structure could also contribute to miscommunication. It is crucial that you provide our personnel with precise instructions, including dimensions, sizes, and the placement of windows and doors. Our experts will also use their knowledge and experience to recommend modifications and alterations that will assist bring your idea to life.

EPACK Prefab has been into manufacturing of pre-engineered and prefabricated buildings for more than two decades. Reach out to us if you have a requirement.