Time is important when we talk about commercial construction. Businesses need industrial factory buildings as soon as they can because a number of operations are lined up for the same. The sooner their structure is ready to function, the more it will minimize downtime and productivity.

Modular factory building manufacturers here are leading the change by providing industrial buildings that are built faster and are durable as well because they are using PEB and prefab techniques.

In this blog, we’ll provide an overview of how this feat is achieved, what the strengths of this new technique are, and showcase the new benchmarks that are being set up by these players in the industry.

Without waiting any more, let’s get started!

What’s PEB construction for industrial factory buildings?

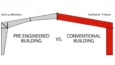

Preengineered building (PEB) construction is a modern approach to building structures. Here, to make a prefab factory, first the components will be manufactured in a facility and then transported to the construction site. Here, these structures will be assembled quickly on site, which will reduce the project timeline and avoid project delays as well.

PEB experts have delivered industrial factory buildings faster and efficiently, and they have managed to provide these services across every industry in India.

How Do Leading Manufacturers Accelerate Industrial Factory Building Projects?

#1 Streamlined Design and Engineering

Top industrial factory building manufacturers who use PEB or Prefab make use of cutting-edge design software, such as ETABS, STAAD Pro, Tekla Structures, and AutoCAD. It enhances the engineering process and reduces chances of human error to a minimum.

The experts in this industry use stringent 180-step quality checks before material dispatch to guarantee that every material is delivered on time, and has the highest standard of quality. There is continuous monitoring from the head office, which enhances the project execution efficiency, and every detail is handled with care.

#2 Optimized Supply Chain and Logistics

In the PEB construction industry, established modular factory building manufacturers have developed a strong supply chain network. This ensures there is timely availability of materials. The strategic partnership with suppliers and logistics providers reduces the transportation delays to a minimum, and there is a seamless flow of materials from factory to construction site.

This is one of the strong reasons why PEB structures take less time to build than traditional ones.

#3 Efficient Manufacturing Process

For building a prefab factory, the entire component of the structure will be built in an expert manufacturing facility. Materials like steel frames, wall panels, and roof systems are made under controlled conditions.

With this process, one can ensure that there is consistent quality, less wastage of material, and less construction timeline. After that, the components are transported to the original site, where these components are joined quickly. This process minimizes on-site work, and reduces the risk of delays caused by weather.

#4 Specialization in Industrial Factory Buildings

Experienced manufacturers focus on specific segments, such as industrial factory buildings, which allows them to refine their processes and offer specialized solutions. For instance, EPACK Prefab specializes in constructing industrial sheds, warehouses, and factory buildings, among other applications. Their expertise in PEB construction enables them to understand the unique requirements of these structures, resulting in faster and more efficient delivery.

#5: Project Management Excellence

Effective project management is vital for delivering industrial factory buildings on time. Leading manufacturers employ experienced project managers who coordinate all aspects of the construction process, from design and fabrication to transportation and assembly. By closely monitoring each stage of the project and proactively addressing potential issues, they ensure that projects are completed within the stipulated timeframe.

India-Specific Data: PEB Adoption and Growth

In India, demand for industrial factory buildings from PEB is on the rise. Just to give an example, the PEB market is projected to grow at a CAGR of 11% from 2024 to 2030. This reflects how important is the industry is getting, and it highlights that people are looking for more such solutions that have faster timelines, sustainable construction, and cost-efficiency in the long run.

Besides, the government’s emphasis on “Make in India” and infrastructure development means that the nation needs more adoption of PEB solutions in the industrial mainstream because it offers quicker turnaround times that will help us beat the international competition.

Case Study: EPACK Prefab’s 150-Hour Factory Build Challenge

A testament to the power of PEB construction is EPACK Prefab’s record-breaking achievement of constructing a 1,151,000 sq. ft. factory building in just 150 hours.

This incredible feat highlights how PEB technology, coupled with efficient project management, can redefine construction timelines.

Choose Prefab/PEB Industrial Factory Buildings!

Speed and efficiency are crucial in industrial construction. Using PEB and prefab techniques, manufacturers deliver projects faster without compromising on quality or durability.

EPACK Prefab is one of India’s leading PEB manufacturers, with over 24 years of experience and 7,400+ projects delivered nationwide.

For your next industrial project, partner with a trusted name.

📞 Contact us at +91-8130444466

📧 Email us at enquiry@epack.in