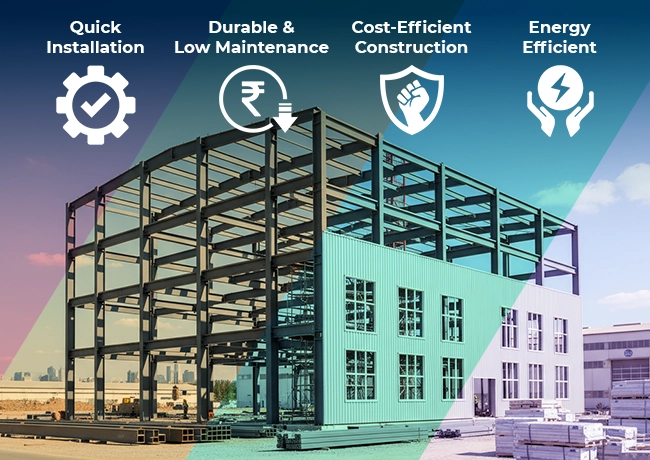

EPACK Prefab is one of India’s leading manufacturers of Pre-Engineered Buildings (PEBs), offering end-to-end solutions for industrial, commercial, and institutional structures. Our buildings are designed using advanced engineering and prefabrication technology, ensuring faster project delivery, cost savings, and custom-built designs for a wide range of applications.

🏗️ What is a Pre-Engineered Building?

A Pre-Engineered Building (PEB) is a steel structure built over a structural concept of primary framing (columns and rafters), secondary framing (purlins and girts), roof and wall sheeting, and other building components. All components are factory-fabricated and then assembled at the site, significantly reducing construction time compared to traditional methods.