Construction is finally evolving in India. Industries have finally understood that it’s possible to reduce energy consumption with a well-built, superior-performance structure.

Which is why they have started to prefer PUF sandwich panels (polyurethane foam), an important component that makes buildings energy efficient. For commercial projects made with PEB, like warehouses, industrial sheds, cold storage, and office buildings, these panels are crucial.

Thus, in this blog, we’ll understand what’s the science behind this Puf sandwich panel, what’s its structure, and how it has become the best choice for a building’s insulation.

The Layered Structure of PUF Sandwich Panels

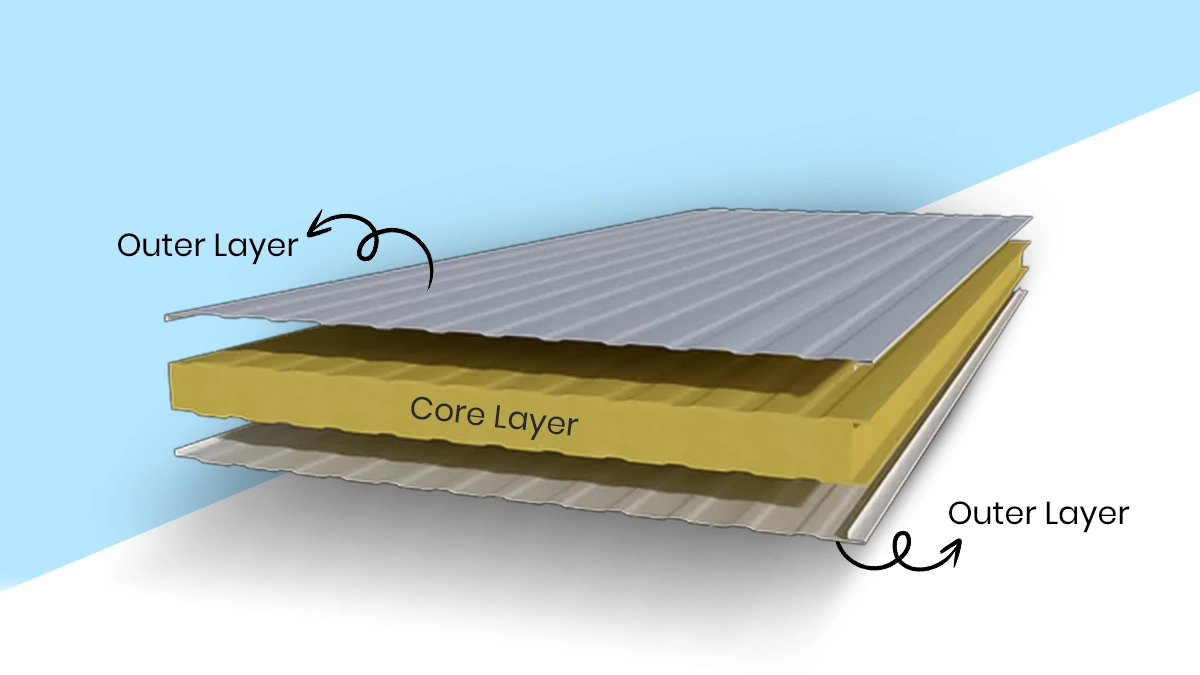

These panels have a core layer that is “sandwiched” between metal sheets. This core layer is made with polyurethane foam. This whole structure and concept have the following benefits:

- Core Layer: As explained, the core is made of rigid polyurethane foam. This form is popular for its fantastic thermal insulation properties. With this form, there is less heat transfer, and the temperature stays consistent in the building.

- Outer Layer: The layers we just mentioned are made of either aluminum or galvanized steel, which provides both durability and protection against external elements. For the changes in metal, one can connect with th-eir PUF panel manufacturer.

- Adhesion: These two layers are bonded together with the help of high-strength adhesives. This keeps the structure’s integrity intact and guarantees its long-term performance. As a result, the structure is lightweight but strong and, at the same time, easy to install.

Thermal Properties and Insulation Efficiency

The main reason for popularity of a PUF sandwich panel is because of its exceptional insulation properties. Here’s why it is superior choice when it comes to insulation:

- Low Thermal Conductivity: The polyurethane foam inherently has low thermal conductivity. Thus, it’s an amazing insulator. Overall, it prevents heat transfer from the external to the internal environment. Due to this, it’s amazing for keeping an environment at constant temperature.

- Saving energy costs: When structures have PUF panels, they require less energy for either heating or cooling the building due to the external temperature. For India, this is very important because our country sees extreme changes in temperature.

- Climate Control: Structures like cold storage and clean rooms need a stable temperature to function properly. PUF insulated sandwich panels can keep the temperature unaffected on the inside, no matter the weather outside. It keeps the stored goods and materials in top shape.

Applications in Various Sectors

PUF sandwich panels are versatile and find applications across various sectors.

- Industrial Sheds and Warehouses: Their thermal insulation properties help maintain optimal working conditions, reducing energy costs.

- Cold Storage Buildings: Essential for preserving perishable goods, these panels ensure minimal temperature fluctuations.

- Clean Rooms and Laboratories: Maintaining a contaminant-free environment is critical, and PUF panels provide excellent insulation and protection.

- Office Buildings and Site Offices: They offer comfortable and energy-efficient spaces for staff.

How Do I Choose PUF Panels from a PUF Panel Supplier?

As a leading PUF panel manufacturer and supplier, we understand what makes a high-quality PUF sandwich panel that can meet diverse requirements. Here are a few things to check out before you pick a puf panel manufacturer for your commercial project.

| Feature | Details |

| Customization | Check if they provide panels in various sizes and specifications to suit different applications, ensuring optimal performance and efficiency. |

| Quality Assurance | Find out if the panels are manufactured using the latest technology and adhere to stringent quality standards, guaranteeing durability and reliability. |

| Expertise | With extensive experience in prefabricated and pre-engineered buildings, we understand the unique needs of our clients and deliver solutions that exceed expectations. Figure out if they have this capability. |

| Durability | Check if they use high-tensile steel and weather-resistant coatings, which ensure longevity and low maintenance. |

Wrapping it up!

Puf roofing panels or sandwich panels can change the way we think about infrastructure. Energy efficiency and superior insulation are highly needed factors for us to build a safe world for the future generation.

These simple, layered foam panels have the properties to drastically reduce a building’s power consumption. Thus, for industrial sheds and cold storage buildings, these are sustainable and cost-saving.

Do you want these amazing panels for your structure? We are here for you! EPACK Prefab is one of the top puf panel suppliers in India. With our 24+ years of experience in the PEB and prefab industry, we have supplied both components and manufactured end-to-end solutions.

Check out our projects to learn about their use cases, or contact us at enquiry@epack.in for your project inquiries.