If you are an architectural student or somebody exploring the scope of Pre Engineered Steel Building Systems, you’ll probably have read about PURLINS.

Purlins are essential horizontal supports in pre-engineered buildings, helping distribute roof loads to the main structure. They come in C-shaped and Z-shaped varieties, usually crafted from cold-formed steel, known for its durability and strength. Well-designed purlins not only boost structural efficiency but also help cut construction costs.

Detailed Role and Characteristics of Purlins

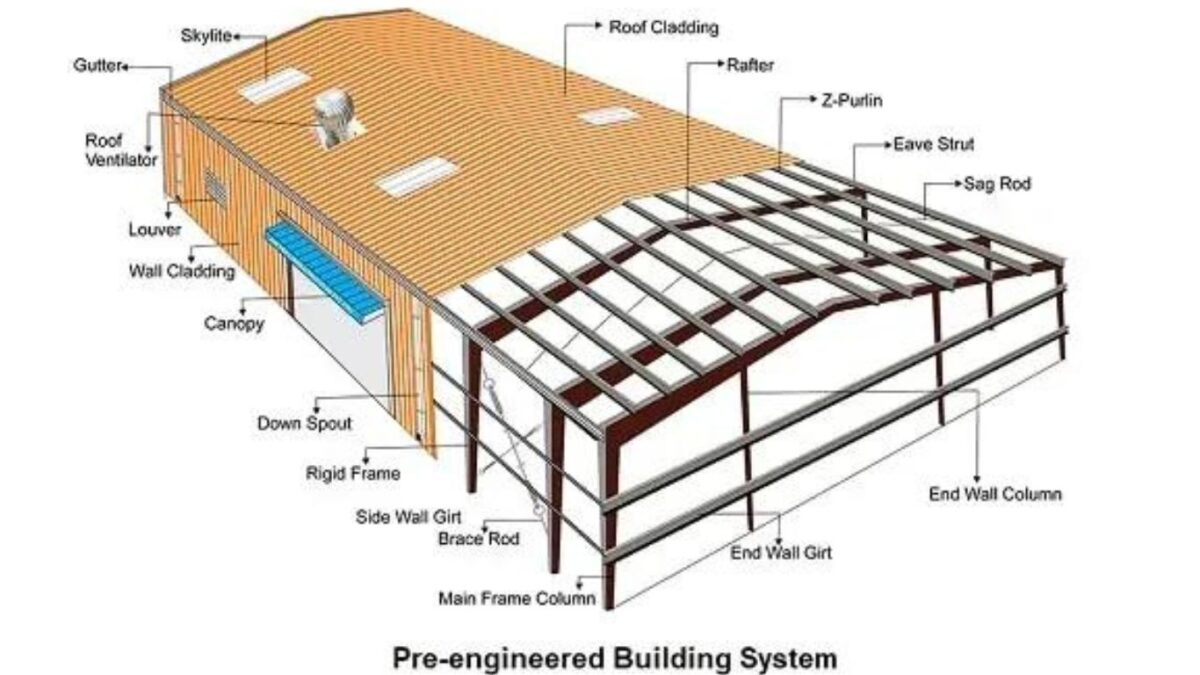

Purlins are steel elements which are used as support structures in pre engineered buildings, mainly below the roofs. Purlins provide extra roof support, creating a horizontal diaphragm that provides support to the weight of the roof and deck. Purlins are installed parallel to the building eave and are supported by rafters or walls. The raw material used to fabricate purlins are cold formed steel. It can span a length of upto 30 feet or longer. The length and width depends on the dimensions of the primary frame of the building, its usage and engineering design. Added stiffness can be given to purlins to prevent loss of structural strength, as required. Purlins are therefore an important part of the roof structure.

In pre engineered buildings, steel purlins are widely used. They are lightweight, durable structures that are built to precision, having consistency in dimensions. Purlins expand and contract in summer and winter respectively.

How Many Types of Purlins Are There?

C shaped Purlins

As the name itself suggests, these purlins bear shape similar to alphabet C. They are commonly used to support walls and floors. C purlins are also sometimes referred to as channel section purlins when they have flange stiffeners and U-sections when they do not. C-sections are those which are mono-symmetrical. These sections cannot be lapped, but the stable shape ensures easy packaging and transportation. The C-section purlins are widely used in clear span design due to their high stability factor.

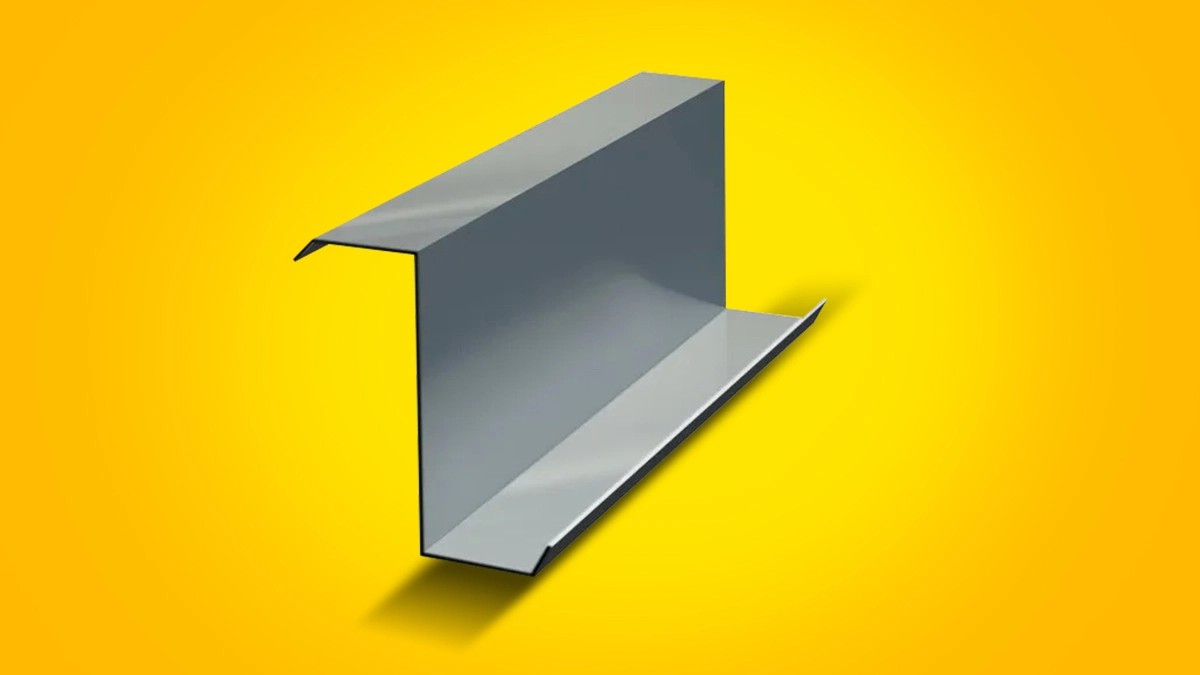

Z shaped Purlins

The Z-shaped purlins are the other type of purlins, which are stronger than C purlins. Z-purlins are most commonly used in joints and overlaps. These purlins are placed between the roofing sheet and wall and provide optimum support to the primary framing system. Z-purlins can be lapped, which is done by rotating one Z-purlin 180 degrees and having it fitted to another one.

What Are The Climate Considerations For Purlins In India?

India’s climate is known for its diversity. From scorching heat to cyclonic storms and heavy monsoons, the variety in the weather poses unique challenges for construction in the region. Purlins, being an important part of Pre Engineered Metal Buildings, must be able to withstand these conditions.

Purlins play a major role in longevity and structural integrity of a building.

Performance in Heavy Monsoons

During monsoons, especially in tropical and coastal regions, we see that structures are predominantly exposed to heavy rainfall and moisture. Here, purlins made with galvanized steel can effectively manage these conditions, as they are corrosion resistant.

Moreover, galvanized purlins with zinc coating also lay a protective barrier. It helps avoid rust, and also extends the lifespan of a building. Also, when purlins are installed with proper drainage design systems in place, it will not let water accumulate, which is often a major reason for structural damage.

Handling Extreme Heat

In regions like Rajasthan and central India, temperatures can soar above 45°C, posing a risk of thermal expansion and contraction of building materials. Purlins made from high-strength steel alloys, which have low thermal expansion coefficients, are ideal for such environments.

Moreover, applying reflective coatings or paint to purlins can significantly reduce heat absorption, keeping the internal temperature of buildings more stable and energy-efficient.

Withstanding Cyclones and High Winds

Eastern coast of India, and other such regions often experience high winds and cyclonic storms. For these areas, strong purlins can protect the building from intense wind loads.

Hot-rolled steel purlins, known for their superior strength and rigidity, are well-suited for such conditions. Additionally, the use of thicker gauge purlins and strategic placement during construction can enhance the wind resistance of the structure.

Effective Materials and Coatings

Usually, it is recommended to use purlins with a combination of high-strength steel and advanced protective coatings so that the structure can withstand all weather conditions easily. For example, epoxy and polyester powder coatings offer an additional layer of protection against UV radiation, chemical damage, and corrosion.

Furthermore, one can ensure maximum durability and minimal maintenance, if they use stainless steel purlins. Industrial areas and regions with salty air are usually highly corrosive environments.

Verdict: Selecting the right type of purlins and protective coatings based on regional climate considerations is crucial for the longevity and safety of prefabricated Steel Buildings in India. Investing in quality materials not only safeguards the structure but also contributes to sustainable and cost-effective construction practices.

Doing Away With Instability In Purlins And Girts

There are two kinds of lateral instability that purlins and girts feature, which are deflection and rotation.

Both these can be reduced significantly by adopting certain engineering methods like bridging and attaching the sheet by fastening screws to provide a lateral brace to the flange to which it is attached.

The process of bridging can help do away lateral deflection of the free flange and rotation of the section.

EPACK’s Commitment to Excellence in PEB Structures

Purlins are quite important from the structural framework point of view in pre-engineered buildings. When high-quality, cold-formed steel purlins are used, builders can be rest assured of the stability and longevity of their structures.

If advanced designs and manufacturing techniques are adopted, the performance of purlins will further enhance, and they’ll become cost effective in modern construction.

Pre Engineered Building Systems are the future of construction. To help understand the technical details, we keep writing blogs that give an insight on the different aspects of this technology. Check them out, and learn more about our technology.

If you are planning to use PEB or Prefab solutions for your business, we can help you! For more information on how EPACK can support your pre-engineered building projects with top-quality purlins and other components, contact us today or visit our website to learn more about our products and services.